There are plenty of good reasons why liquid-fuelled piston engines dominate land and sea transportation. They are better than older technologies. And usually, when some alternative technology tries to challenge the dominance of liquid fuels and piston engines, we add another item to the list of reasons why liquid-fuelled piston engines are best.

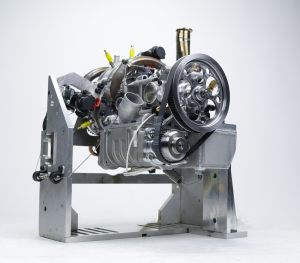

A small company in Connecticut has come up with a rotary engine that looks like a genuine challenger to the piston engine. LiquidPiston’s rotary engine has been demonstrated as a four-stroke compression ignition (diesel) and four-stroke spark ignition engine. Now, the company is developing a two-stroke variant of their “X engine”. LiquidPiston’s rotary concept is potentially less complex and smaller than equivalent piston engines. Unlike the Wankel, the X engine also promises better fuel economy.

LiquidPiston’s 70 cc “X Mini” is a port-injected air-cooled spark ignition engine that burns gasoline, jet fuel, or hydrogen, producing up to 3.5 horsepower. A prototype X-Mini has been demonstrated on a go-kart.

The X Mini’s larger sibling is the 750 cc naturally-aspirated liquid-cooled “X4”. LiquidPiston reported in technical papers published by the SAE that the X4 has operated with compression ratios up to 26:1, plenty high enough for compression ignition operation.

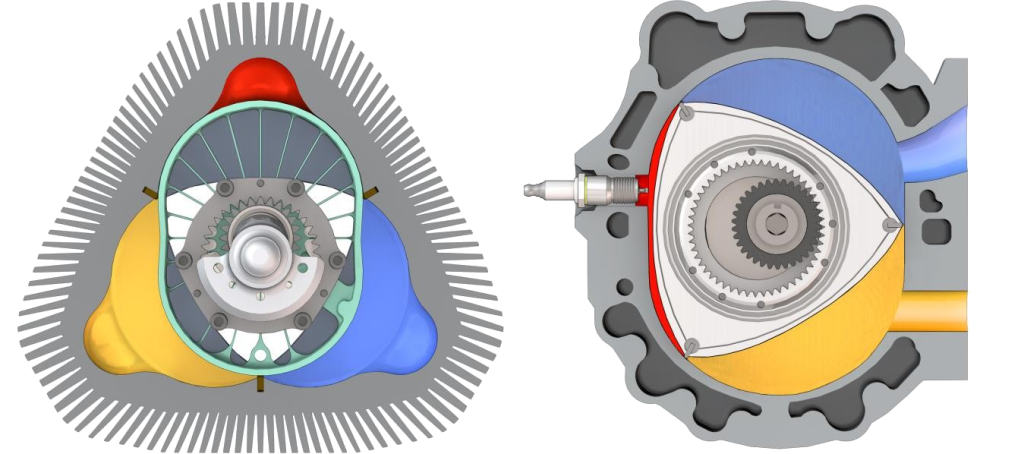

Using a kidney-shaped rotor instead of a piston, LiquidPiston’s X engine is the first practical rotary engine since the Wankel was commercialised in the 1950s. Like the Wankel, the new engine’s rotor wobbles like a hula-hoop around an eccentric gear. That’s about where the similarity ends.

The X engine’s outer housing provides three combustion chambers, separated by seals which wipe against the rotor’s outer surface. This gives the engine designer total freedom to design the combustion chambers; The seals do not affect combustion chamber geometry.

LiquidPiston was established in 2004 by Nikolay Shkolnik and his son Alexander Shkolnik (currently LiquidPiston’s CEO). Their goal was to develop a practical internal combustion engine based on a high-efficiency operating cycle patented in 2003 by Nikolay Shkolnik. This theoretical operating cycle, called the “High Efficiency Hybrid Cycle” (HEHC) aims to deliver better fuel economy than is achievable with conventional gasoline (Otto cycle) and diesel (Diesel cycle) engines. The challenge was to find a configuration that could perform a couple of tricks that piston engines can’t. The HEHC involves burning the fuel under constant volume conditions. Piston engines don’t do this. In addition, the HEHC calls for an expansion ratio which is greater than the compression ratio. This is possible with an Atkinson cycle piston engine such as the 1400 cc Toyota Prius engine. But that’s an oddball.

The Shkolniks and their team tried several configurations, including one that featured a liquid piston, before coming up with the rotary X engine concept. The X engine’s combustion chambers are easily configured for constant volume combustion. According to LiquidPiston, constant volume combustion leads to better fuel efficiency. The format also makes it easy to achieve the HEHC’s high expansion ratio, allowing combustion gases to fully expand before they go out the exhaust. This further improves fuel economy compared with conventional diesel and gasoline engines.

LiquidPiston’s latest engine is the 210 cc, 25 horsepower, supercharged, liquid-cooled spark ignition XTS-210, which is destined for a portable 10 kW generator for military applications. The XTS-210 adds a new trick to the X engine’s already compelling repertoire: 2-stroke operation. Previous X engines ran on a four-stroke cycle, firing three times for each revolution of the rotor. The rotor in these engines has a hot end and a cold end. The engine fires as the hot end passes through each of the three combustion chambers. In the two-stroke XTS-210 both ends of the rotor are hot. The engine fires each time each end of the rotor passes through a combustion chamber. With two ends on the kidney shaped rotor, and three combustion chambers, that’s six combustion events per rotor revolution.

Like the GMC 71-series two-stroke diesels, the XTS-210 has a small blower to aid scavenging. As in the X mini and X4, the XTS-210’s output shaft turns at twice the rotor rpm, due to the gearing system. LiquidPiston reported in April this year that the XTS-210 prototype had successfully completed dynamometer testing.

The X engine looks like a genuine step forward: An alternative that can do everything a piston engine can do, only better. Like a piston engine, the X engine needs the right kind of transmission system. The power and torque curves published in LiquidPiston’s datasheets reveal an engine that does not have a lot of low-down torque. That’s OK with electric or hydraulic hybrid transmissions. Most internal combustion powered vehicles will eventually need hybrid systems to comply with air quality regulations. Exhaust emission rules in Europe and the USA are now so tight that particles from braking systems are the dominant source of avoidable air pollution from road vehicles. Hybrid systems feature regenerative braking, which eliminates the problem of brake emissions.

LiquidPiston’s original mission was to invent a more efficient engine. Their US government projects give them the opportunity to develop their prototypes into practical engines capable of doing a job of work. The X engine has a lot going for it. A more fuel-efficient engine means fewer gas station visits. Already, the average New Zealand motorist can expect their ute or SUV to go three or weeks or so on a tank of fuel. With more efficient engines, we can look forward to going four or five weeks between fuel stops

The X engine also promises quiet, silky-smooth operation. With no reciprocating parts, a multi-rotor X engine should be practically vibration-free. It should be quiet, too. The HEHC’s high expansion ration means less exhaust noise, because all the combustion energy is used to drive the rotor. You won’t hear camshafts whacking their followers, poppet valves bashing their seats or pistons slapping their cylinders because the X engine has none of those things.

LiquidPiston has published a wealth of data on their progress with the X engine, and they’ve been open about some of the problems they’ve had to deal with. I hope they keep doing that.

The Shkolniks and their team a lot of work ahead of them. I’m looking forward to the next chapter in this very interesting story.

We are technorg.